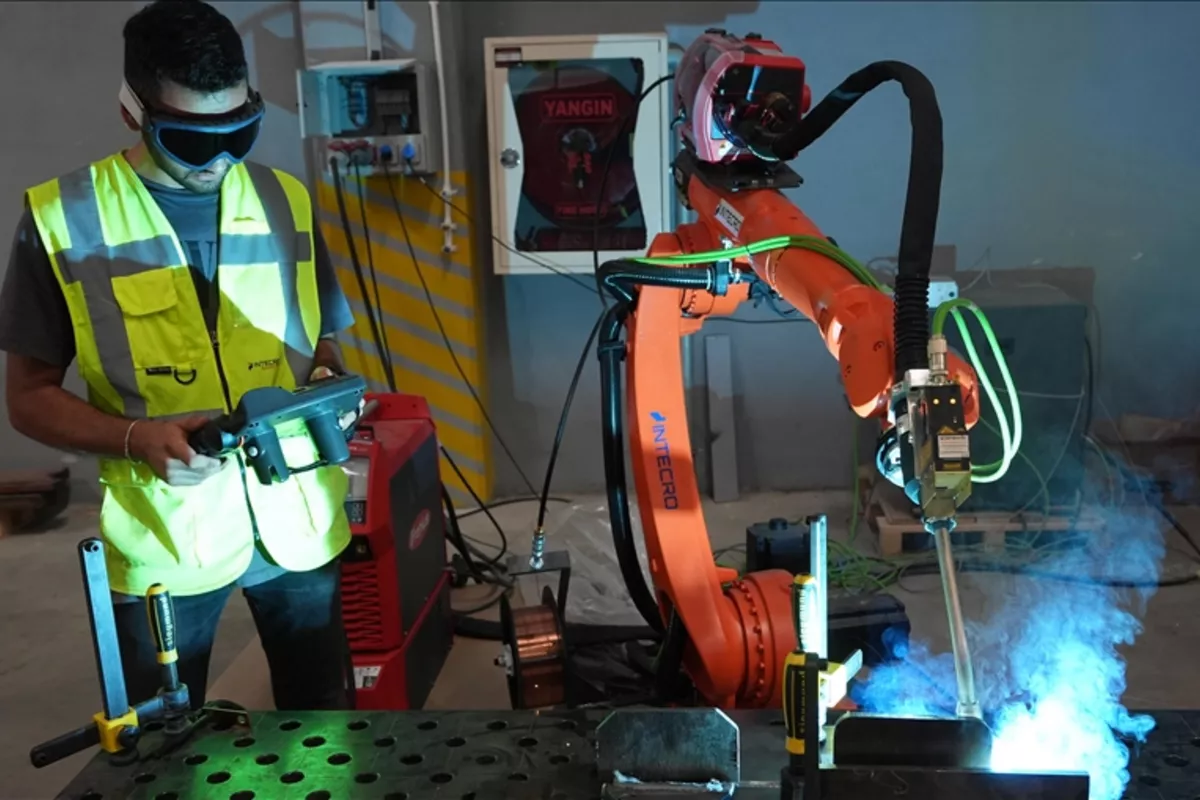

Photo: Anadolu Agency

Türkiye’s defense industry has begun integrating next-generation industrial robots into its production processes, marking a significant shift toward automation and advanced manufacturing.

The use of these cutting-edge robots has also become widespread in sectors such as automotive, aviation, shipbuilding, and construction machinery, The Caspian Post reports, citing Anadolu.

Intecro Robotics, a Turkish company, develops and implements robot-based industrial production systems and solutions for multiple sectors. “There’s hardly any industry left without robot technology at work,” the company’s chair, Ali Sen, told Anadolu.

Sen said the defense and aviation sectors have benefited from global trends, with more companies worldwide adopting robotics for production.

"Many firms in developed countries producing ammunition and rockets have integrated and popularized next-generation production technologies for years, bringing improvements to mass production, speed, and performance-focused manufacturing," he said. "We began to establish such robot-based production systems in the defense industry in 2013."

Intecro has worked with major Turkish defense firms, including MKE, Roketsan, Turkish Aerospace Industries (TAI), and Aselsan.

"In today's factories, digital twins - virtual models of the actual product and physical end-product or process - are as important as robotics," Sen said.

He noted that sensor fusion, where multiple sensors cooperate to generate production data, is becoming more prominent.

Intecro has set up production lines for various weapons and ammunition systems, including penetrating bombs and infantry rifles for MKE and atomic ammunition for Aselsan. The company is also developing mass production technologies for different ammunition types, electro-optical systems, and other defense systems for MKE and Aselsan.

Sen said Intecro’s robots will be used in welded production processes to assemble high-strength armor steels, performing the work with precision and ensuring welding meets required standards.

“These robotic systems have an intuitive and adaptive aspect; they can detect minor defects and analyze manufacturing errors that may occur during the pre-welding preparation process,” he said.

Serhat Ugural, Intecro’s general manager, said the company’s robotics solutions have been deployed in various projects in Türkiye and abroad.

“Our three main sectors are aviation, automotive and electromobility, and general industries involving metal processing, such as railway cars, ships, commercial vehicles, machinery, heavy vehicles and the energy sector,” he said.

“The majority of the production lines at Siro - the firm producing batteries for Türkiye’s electric vehicle brand Togg - were established by Intecro,” he said, adding the company also develops production technologies for other automakers such as Renault and Tofas.

Ugural said Intecro tailors technologies for each sector through research, the latest being its “machine intelligence research and development program,” which enables robots to analyze, learn, and perform tasks autonomously, also known as self-programming.

“We established two different robotic welding systems with these robots that received positive reception from many domestic and international firms.”

He mentioned that Intecro also produces robotic production lines for the locomotive and wagon industry for Turkish firms like Turasas, Vako Vagon, and Gok Rail, while producing metal shaping robotic technologies for heavy industry firms like Isuzu, MAN, Erkunt, Otokar, Bozankaya, Hyundai Rotem, Putzmeister, ZF Sachs, Mahindra, and Turkish Scientific and Technological Research Institution (Tubitak) SAGE.

Share on social media